Digitalization has become a strategic priority for industrial companies seeking to be more competitive, efficient, and sustainable. However, many organizations still wonder: where should we begin this process? In this article, we explore the key first steps to successfully start a digital transformation in an industrial plant.

What is industrial digitalization?

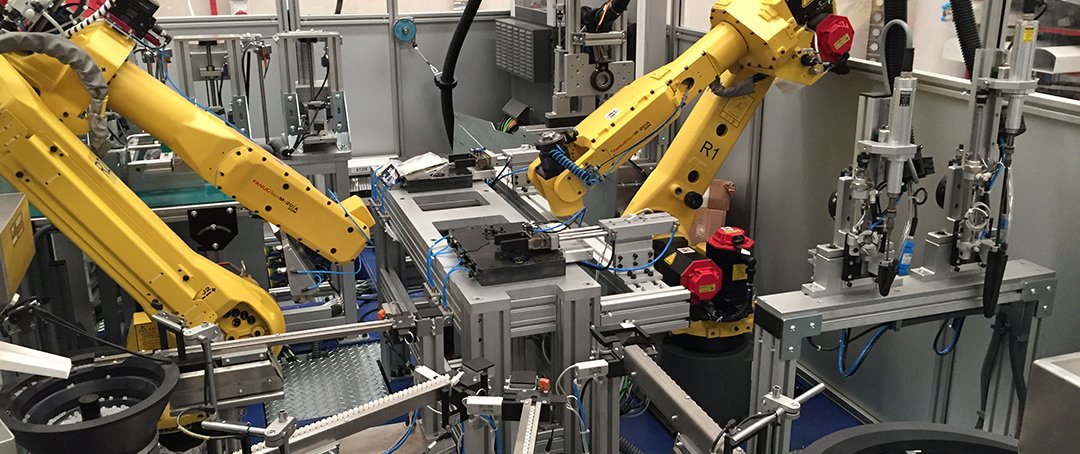

Digitalization in industry involves integrating digital technologies to automate, monitor, and optimize processes. This includes the use of sensors, SCADA systems, Industrial IoT (IIoT), data analytics, artificial intelligence, and predictive maintenance.

Benefits of digitalizing an industrial plant

- Increased operational efficiency

- Real-time, data-driven decision-making

- Reduced downtime and equipment failures

- Energy and resource savings

- Greater process traceability and control

Step 1: Assess digital maturity

Before investing in technology, it’s essential to understand your plant’s current status. An initial assessment helps identify critical areas, bottlenecks, and the existing level of automation and connectivity.

Step 2: Set clear objectives

Digitalization should address specific needs. Do you want to improve energy efficiency? Reduce downtime? Automate production reports? Define specific, measurable goals to align your technology strategy with your business objectives.

Step 3: Start with pilot projects

Instead of trying to digitalize the entire plant at once, begin with a pilot project in a key process. This allows you to validate technologies, measure return on investment, and gain experience with lower risk.

Step 4: Choose the right, scalable technology

Select technological solutions that fit your needs and can integrate with your current systems. Ensure they are scalable to support your plant’s future digital growth.

Step 5: Training and cultural change

Digital transformation is also about people. Train your teams and promote a culture of innovation and continuous improvement. Resistance to change can be a bigger obstacle than the technology itself.

Step 6: Measure and continuously improve

Implement key performance indicators (KPIs) to evaluate the impact of digitalization. Use the collected data to fine-tune processes and move toward smarter operations.

Conclusion

Digitalization is not a destination, but an ongoing journey. Starting with well-defined steps, focusing on results, and having the right support will allow your industrial plant to confidently move toward Industry 4.0. At Promimex, we support our clients along this path by providing solutions and technical guidance aligned with their operational challenges and transformation goals.

Other Publications How to Choose the Right Industrial Equipment for Your Application How Lime Slurry Preparation Plants Work Basic Glossary of Technical Terms for Industrial Clients What is a Filter Press and What Is It Used for in Mining? Industrial Water Treatment: Innovation and Environmental Responsibility

Posts Categories Education and Best Practices Process Optimization Sustainability and Technology Technical and Product Topics Trends and Industry

Products & Services Pumping Systems for Industrial Processes Shutdowns & Turnarounds Services (Evoqua) Membrane Services (Evoqua) Amphibious Multipurpose Dredges (Dragflow) Solid-Liquid Separation (TecProMin) PEMO Triple Casing Pumps (Pemo Pumps) Sludge Thickeners (Diemme Filtration) Automated Flocculant Preparation Systems (TecProMin) Lifting Platforms (Corental) Hydraulic Dredging Pumps (Dragflow)