More Diemme Filtration Products:

Sludge Thickeners

KE Filter Press

Side beam Filter Press AUTOMAT

Side beam Filter Press ME

Overhead beam Filter Press GHS

Overhead beam Filter Press GHT-P

GHT5000F Domino

More Diemme Filtration Products:

Sludge Thickeners

KE Filter Press

Side beam Filter Press AUTOMAT

Side beam Filter Press ME

Overhead beam Filter Press GHS

Overhead beam Filter Press GHT-P

GHT5000F Domino

Strengths

- Fully automatic machine

- Minimized cycle times

- High levels of dewatering

- Reduced component wear

- Low operating costs

- Dual cloth washing system (low pressure and high pressure)

- Quick and simple cloth replacement system

- Integrated platform for safe maintenance operations

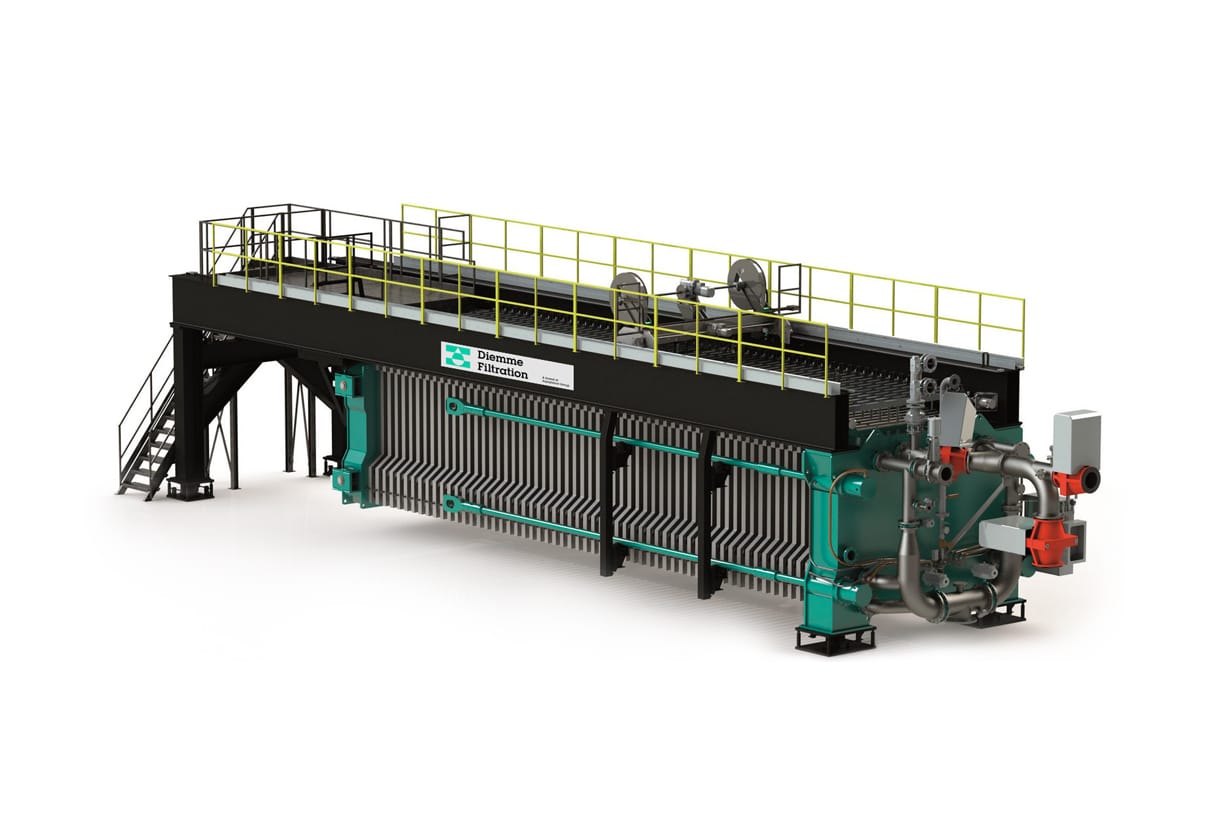

The GHT-F is a filter press by Diemme® Filtration specially developed for large volumes of material to be processed and for highly filterable products such as concentrates and tailings. The movement of the mobile head, electrically driven, and the simultaneous opening of the plate pack considerably reduces the discharge time and the entire opening and closing sequence of the filter (up to 141 plates in 1 minute). The result is a fast-cycle filter press that significantly increases productivity for the same filtration area.

The high side-beam structure of the GHT-F filter press facilitates the installation of various devices that enhance its performance, such as the cloth washing system and the cloth shaking system. In addition, routine maintenance operations are easier thanks to an integrated platform that allows access to the machine from above. The filter plate pack is secured using four hydraulic cylinders that use the “pull-to-close” locking system, which keeps the machine operational and counteracts any misalignment.

Design Features:

Technical Sheet

- Dual beam

- Simultaneous plate pack opening and closing system

- Automatic high-pressure cloth washing device

- Rain-style automatic cloth washing system

- Plate shaking device

- Load cells

- Multiple feed system

- Optimization of fluid velocity within the pipes

- PLC (human-machine interface)

- Integrated maintenance platform

- Also part of this range of filter presses is the giant Domino GHT5000F, the largest filter in the world, featuring plates with a nominal size of 5000 x 5000 mm.