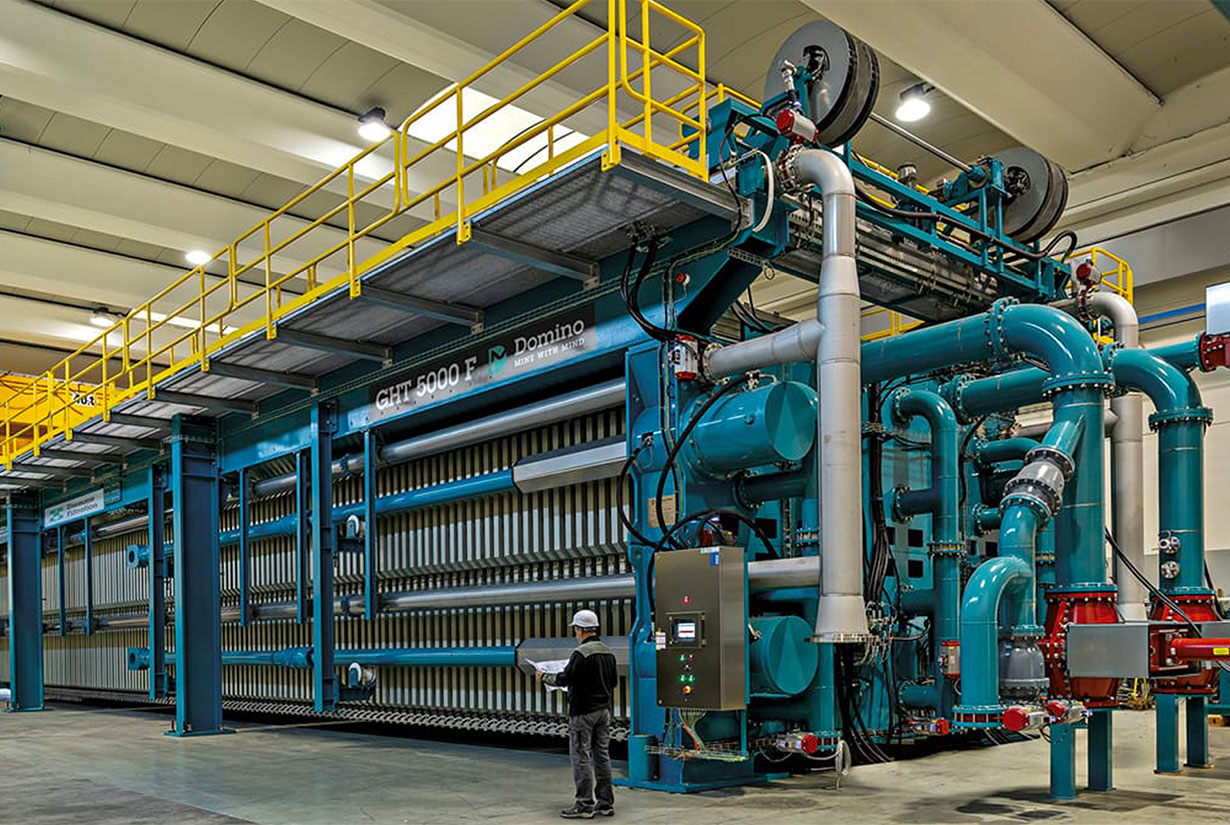

GHT5000F Domino

More and more, mining companies are extracting enormous quantities of ore. Once the ore is concentrated, a huge amount of waste remains—called tailings—that requires careful and demanding handling. Tailings filtration and dry stacking are increasingly being chosen as the best waste management technologies. The scale of these large mines and the corresponding production of waste slurry requires filtration equipment specifically designed to handle these dimensions.

More Diemme Filtration Products:

Sludge Thickeners

KE Filter Press

Side beam Filter Press AUTOMAT

Side beam Filter Press ME

Overhead beam Filter Press GHS

Overhead beam Filter Press GHT-P

GHT-F Overhead Beam Filter Press

More Diemme Filtration Products:

Sludge Thickeners

KE Filter Press

Side beam Filter Press AUTOMAT

Side beam Filter Press ME

Overhead beam Filter Press GHS

Overhead beam Filter Press GHT-P

GHT-F Overhead Beam Filter Press

Strengths

Diemme® Filtration has been able to design and manufacture the first in this new generation of enormous filter presses, capable of tripling the production capacity of the largest filter press currently in operation.

The new filter press is called the “GHT5000F Domino” and retains all the strengths of the GHT-F models. In addition, it offers the following features:

- IIoT for remote control, management, and optimization (see our AIDA system tutor).

- Integrated platform to simplify maintenance.

- Spray washing system with 6 wash points for uniform cloth cleaning.

- Automatic high-pressure cloth washing with dual bars (for technical downtime reduction).

- Minimal wiring system to allow for quick plant installation.

- Beam components can be easily shipped and just as easily reassembled at the customer’s site.

- Quick replacement system for multiple layers on both sides of the filter.

Benefits

Technical Sheet

With a filtration volume of up to 71 m³ and a maximum total filtration area of 2,850 m², the GHT5000F Domino filter press is the largest on the market. The high performance will significantly improve the initial investment costs compared to a tailings filtration plant using many more smaller filter presses to achieve the same productivity. In each case, it will be possible to evaluate savings in the Total Cost of Ownership (TCO) by including operational cost savings in the equation.