The OMS Presse Ladles Unit is a highly efficient solution for automating the metal pouring phase in cold chamber die casting processes. Specifically engineered to work seamlessly with OMS Presse’s range of die casting machines, this ladling unit ensures precise and consistent transfer of molten metal from the furnace to the shot sleeve—minimizing waste, improving safety, and boosting production performance.

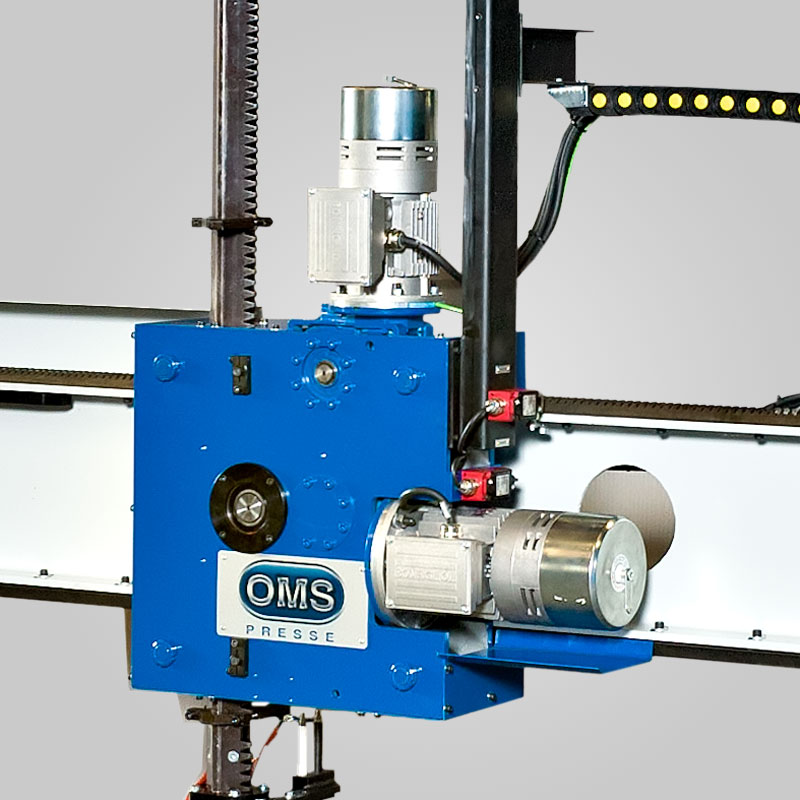

Built with durability and reliability in mind, the ladles unit features advanced mechanics and electronics to handle high temperatures and frequent cycles with minimal maintenance. The movement system allows for synchronized, smooth, and accurate positioning during the pouring process, making it ideal for high-volume and precision-focused casting operations.

Designed and manufactured in Italy, OMS Presse’s ladles units combine solid construction with smart engineering to support the productivity, repeatability, and longevity of your die casting line. Whether you’re working with aluminum, magnesium, or brass alloys, this unit integrates easily into your automation flow and enhances overall operational efficiency.

Specifications

- Compatibility: Cold chamber die casting machines (350 to 3500 tons)

- Ladle Capacity: Customizable to suit production volume and alloy type

- Pouring Accuracy: High-precision positioning system

- Control System: Fully programmable with touchscreen interface

- Drive System: Servo-controlled or hydraulic (depending on model)

- Construction: Heat-resistant, reinforced steel and ceramic components

- Cycle Time: Optimized for fast and repetitive operations

- Maintenance: Low-maintenance design with easy-access components

- Integration: Designed for seamless automation with OMS Presse systems