The filter press is an essential piece of equipment in various industrial processes, especially in mining, where it is used to separate solids from liquids in suspensions. This equipment plays a crucial role in the treatment of minerals, water, and other liquids, helping recover valuable resources and ensuring the sustainability of the process.

What is a Filter Press?

A filter press is a device used to separate solids from liquids in industrial processes by applying pressure. The equipment consists of a series of plates and frames that are assembled to form a set of chambers where the material to be filtered is introduced. The liquid passes through the filter fabrics, while the solids are trapped in the chambers, forming a filter cake.

This type of filter is highly efficient in separating solid particles from liquids and is widely used in industries that require high-efficiency separation, such as mining, chemical industries, and water treatment.

How Does a Filter Press Work in Mining?

In mining, the filter press is mainly used for the treatment of sludges and other materials resulting from the mineral extraction process. The filtration process is carried out as follows:

- Loading the Material: The sludge or mineral suspension is introduced into the filter press, where it is evenly distributed among the filter chambers.

- Applying Pressure: Once the material is in place, pressure is applied to the chambers to force the liquid through the filter fabrics. This allows the solids to remain trapped in the chambers, forming a filter cake.

- Discharging the Filtered Liquid: The filtered liquid passes through the meshes and is collected for further treatment or reuse.

- Discharging the Solid Cake: Once the desired filtration level is achieved, the filter is opened, and the solid cakes are discharged, which can be processed or disposed of depending on the material type.

Applications of the Filter Press in Mining

The filter press is especially useful in the following processes within the mining industry:

- Wastewater Treatment: In mining, proper treatment of wastewater is crucial to prevent contamination. The filter press helps separate solids from effluents, allowing for water recycling for other processes.

- Recovery of Precious Metals: In some mining operations, the filter press is used to recover valuable metals from sludges resulting from extraction processes, such as gold and silver.

- Separation of Sludges and Tailings: The sludges generated from flotation and other extraction methods contain a mixture of water and solids. The filter press is used to separate solids from liquids, creating a filter cake that is easier to handle and store.

- Handling Chemicals: In certain mining operations, chemicals are used to treat minerals and improve extraction efficiency. The filter press helps separate these chemicals from residual solutions, ensuring proper handling and disposal.

Advantages of the Filter Press in Mining

- High Efficiency in Separation: The filter press offers high filtration capacity, allowing for the separation of a large amount of solids from liquids with excellent quality.

- Water Recycling: It helps maximize water recycling in mining, a crucial and increasingly limited resource in many regions.

- Reduced Environmental Impact: By separating solids from liquids, the filter press helps reduce water pollution and improves waste disposal in mining.

- Resource Optimization: It facilitates the recovery of precious metals and other resources, which can enhance the profitability of mining operations.

Conclusion

The filter press is a fundamental piece of equipment in modern mining. Its ability to efficiently separate solids from liquids helps improve water treatment processes, the recovery of precious metals, and waste management. By integrating this type of technology into mining operations, resources are optimized, and the environmental impact is reduced, contributing to more sustainable and efficient mining practices.

Other Publications The Future of the Automotive Industry and the Role of Industrial Technology Digitalization in Industrial Plants: Where to Start? Industrial Water Treatment: Innovation and Environmental Responsibility Process Automation in Reagent Plants: Key Benefits Preventive Maintenance for Industrial Equipment: What You Need to Know

Posts Categories Education and Best Practices Process Optimization Sustainability and Technology Technical and Product Topics Trends and Industry

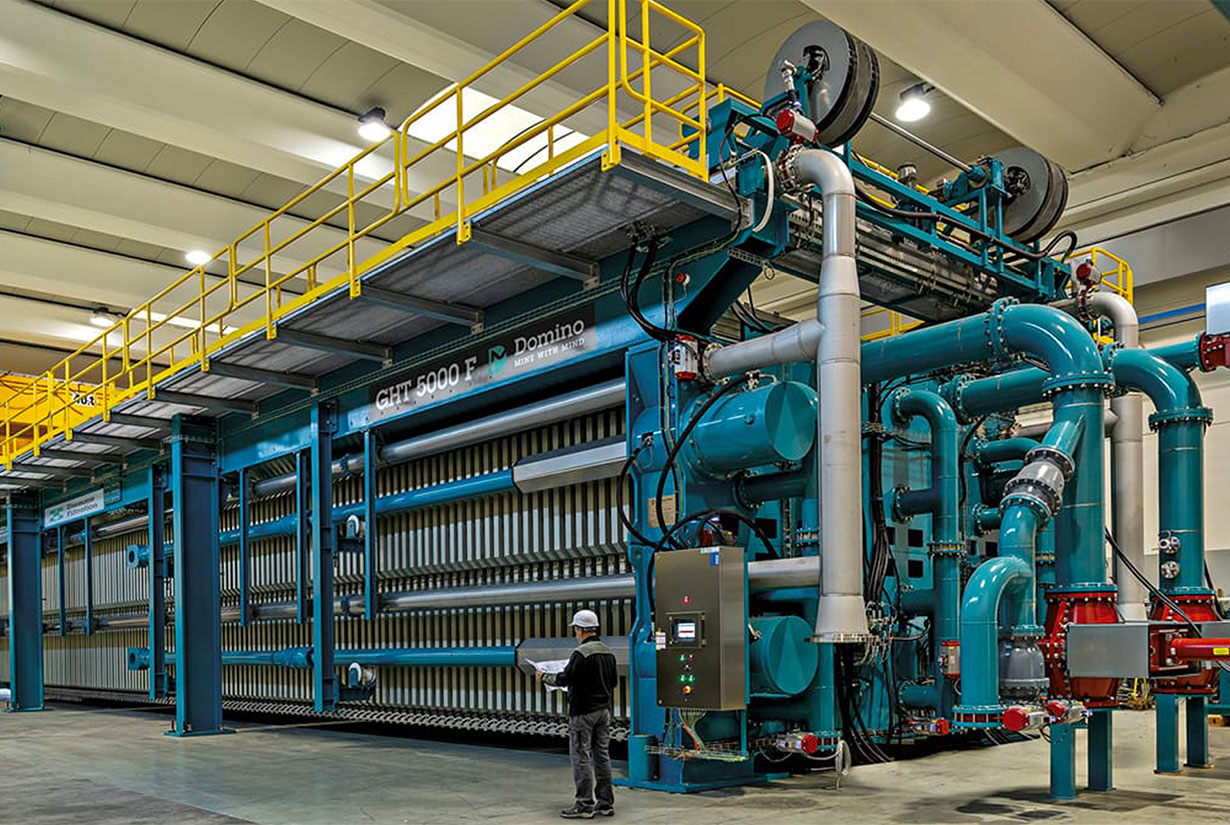

Products & Services AO/TI and AO/TD (Pemo Pumps) AO/AB/DC Series (Double Casing) (Pemo Pumps) Electric Dredging Pumps (Dragflow) Municipal Odor and Corrosion Control Services (Evoqua) Steel Cable Dredges (Dragflow) Water and Slurry Test Graphs Pumps Accessories (Dragflow) GHT5000F Domino (Diemme Filtration) OMS Presse Working Cell (OMS Presse) Agitation Systems for Metallurgical Processes